Cowpea Peeling Machine Cowpea Peeler

Cowpea peeling machine can remove cowpea beans skin and produce grade peeled cowpea beans

kernels. Cowpea beans provides special support for digestive tract health, and particularly our colon.

The indigestible fraction (IF) in cowpea beans has recently been shown to be larger than the IF in

either lentils or chickpeas. Under many circumstances, we need to peel cowpea beans to improve

cowpea beans edible value.

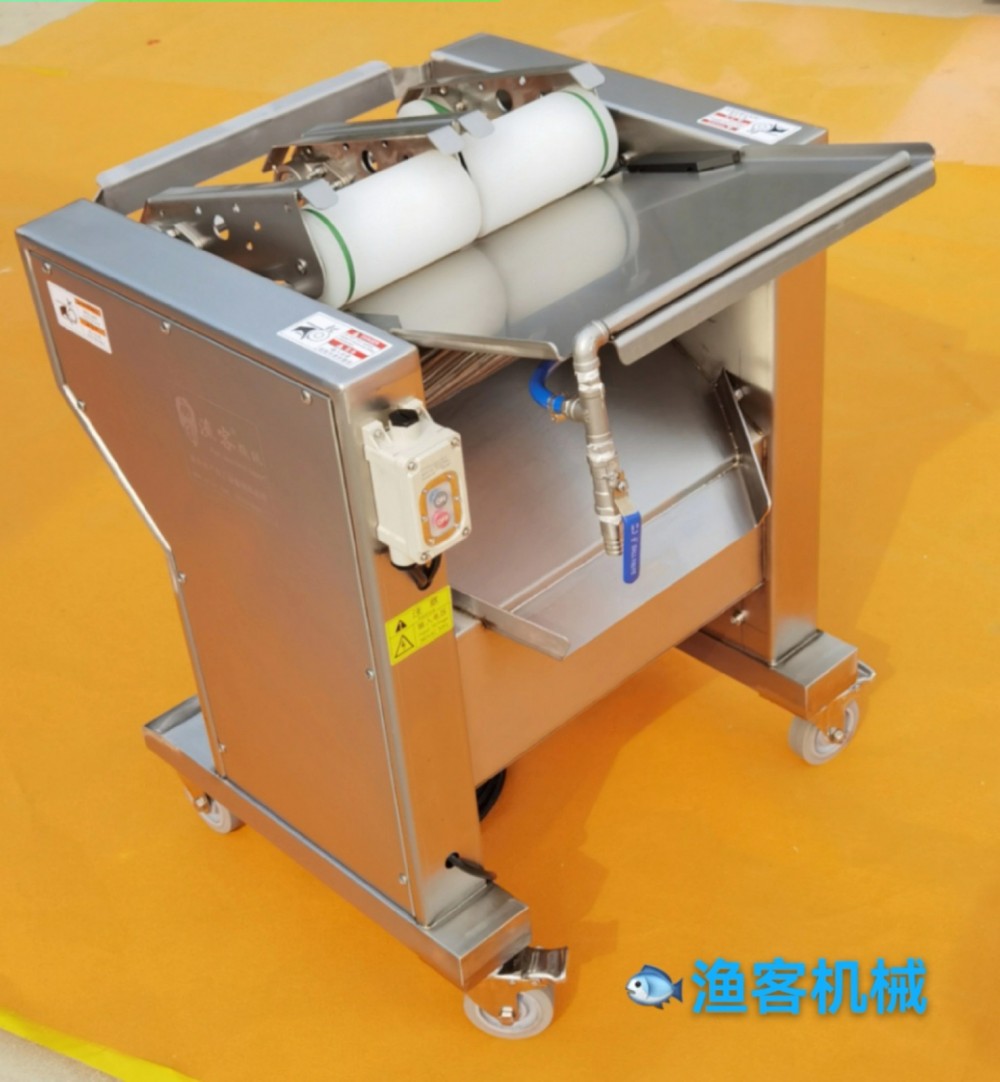

Cowpea peeling machine uses high-speed rotating emery roller to cut and rub the cowpea cortex

continuously, and the process destroys the bonding strength between cowpea endosperm and

cowpea embryo, which can produce qualified peeled cowpeas. It has highly efficient air suction

chamber inside to collect the bean cortex from peeling process. The bean peeling rate can reach

95% above. Cowpea peeling machine is composed of charging device, spiral conveyor, peeling

chamber, transmission gear, aggregate bin, discharge device and dust catcher.Cowpea peeling

machine can work independently as a single machine and also can work in the processing plant

which consists of other sections, such as cowpea cleaning, destoning, brushing, cowpea flour

milling and so on.

Cowpea peeling machine technical parameter: (Letter A means external air

blower. Letter B means internally installed air blower)

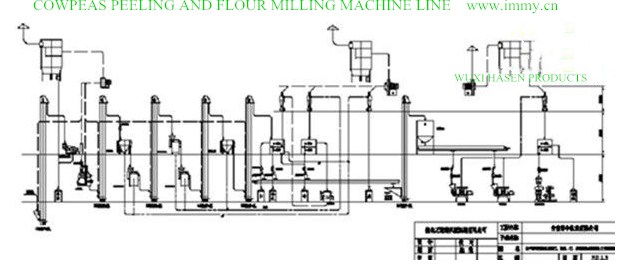

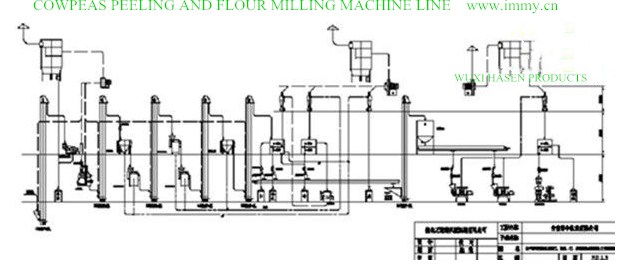

Cowpea Peeling and Flour Milling Plant

Cowpea peeling and flour milling plant can process cowpea by cleaning,

peeling, milling and packaging. Cowpea peeling and flour milling plant consists

of cowpea cleaning machine, cowpea peeling machine, cowpea milling machine

and cowpea packaging machine. From cowpea peeling and flour milling plant,

we can get peeled cowpea kernels, cowpea grits and cowpea flour.

Cowpea peeling and flour milling plant working process:

1. Bean cleaning section: it adopts two screening sections, two destoning sections,

one magnetic separation section, and removes the big, small and light impurities,

pebbles and magnetic material from the beans to ensure the quality of the

end products.

2. Bean color sorting section: it adopts the color sorter to separate the moldy kernels,

shriveled beans and foreign species of beans according to the color and luster

feature of the beans.

3. Bean peeling section: it adopts peeling, brushing and shunting technology

(it can utilize the segregation valve to choose peeling and brushing according to

the material character.)

1)Peeling: it can peel the bean bran and separate and collect it by effective

aspiration system;

2)Brushing: it can separate the micro bran and dust which adheres to the

material surface.

4. Grading section: it adopts different screens and classify the material into

different grades according to the size.

5. Bean kernel making and grits milling section: it adopts the technology of

three peeling sections, one grits making section, grading and suspension.

1)Peeling section: it can peel the bean bran and separate and collect it by

effective aspiration system and produce whole peeled kernels;

2) Bean grits making section: it uses fine bean grits machine and mill beans

into bean grits;

3) Bean kernels and bean grits grading section: it adopts different screens

and classifies bean kernels or bean grits into different grades according

to the size.

4)Suspension: it separates bean bran by utilizing airflow according to different

material gravity.

6. Bean flour milling section: it adopts the technology of burdening, several

processes of grinding and screening and grading.

1)Burdening: it can mix different material according to different requirements

for different products;

2)Grinding: it can grind or mill the beans into fine bean flour by the professional

bean grinder;

3)Screening: it separates the bean flour.

Soy flour and grits enhance the nutrition and texture of products. Available

in a variety of granulations, soy flour and grits have multiple uses, including

extending the freshness and shelf-life of many foods.

7. Measuring and packaging section: storage can reduce the amount of labor used.

Measuring can be artificial or electronic.

Cowpea peeling and flour milling plant technical parameter:

Type | Power (kw) | Power Consumption(kw/h) | Capacity (t/24h) | Workshop Dimension(l*w*h/m) |

10t | 24 | 38-40 | 10 | 10*4*4 (steel structure) |

20t | 56 | 38-40 | 20 | 16*5*5 (steel structure) |

30t | 72 | 38-40 | 30 | 20*5*5 (steel structure) |

50t | 119 | 38-40 | 50 | 20*5*7 (steel structure) |

100t | 238 | 38-40 | 100 | 30*5*7 (steel structure) |